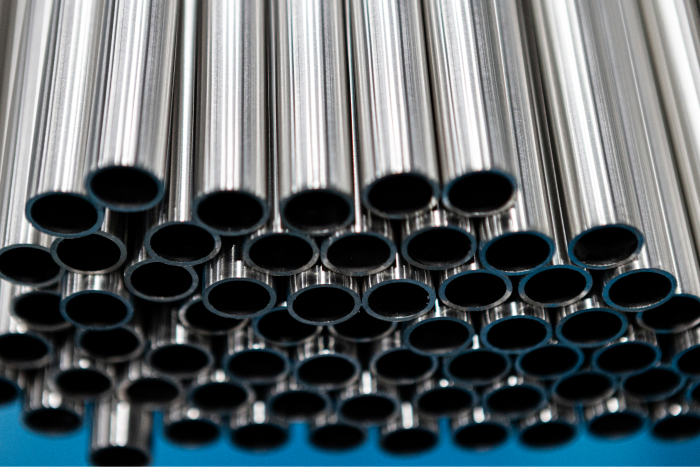

Nickle Alloy Materials

Nickle alloy refers to a kind of alloy with comprehensive properties such as high strength and certain anti-oxidation corrosion ability at 650~1000℃. The main alloy elements are copper, chromium and molybdenum, which can withstand various acid corrosion and stress corrosion of nickle-based alloy in many fields, such as:

1. Ocean: Marine environment, sea water desalination, sea water aquaculture, sea water heat exchange, etc.

2. Environmental protection field: flue gas desulfurization device for thermal power generation, waste water treatment, etc.

3. Energy field: nuclear power generation, comprehensive utilization of coal, tidal power generation, etc.

4. Petrochemical field: oil refining, chemical and chemical equipment, etc.

5. Food field: salt making, soy sauce brewing, etc.

In the above fields, ordinary stainless steel is not competent, but nickle alloy is indispensable, and cannot be replaced in these special fields. In recent years, with the rapid development of the economy, and the continuous improvement of the level of the industrial field, more and more projects need a higher grade of stainless steel. With the increase of demand for nickle alloy in various industries, Yinhuan took nickle alloy as the company's main product at the beginning of its establishment, and successively produced a variety of nickle alloy tubes, which were recognized by customers.

Product

Duplex (Super Duplex) Stainless Steel Seamless Tubes

This kind of steel has the characteristics of Austenite and Ferritic stainless steel. Compared with ferritic steel, it has higher plasticity and toughness, no room temperature brittleness, and significantly improved intergranular corrosion resistance and welding performance.

Stainless steel High purity BA/EP Tubes

Clean pipe tube with smooth surface, high precision tolerance, excellent inner surface roughness, inner surface Ra < 0.4 m characteristics.

Nickle Alloy Materials

Nickle alloy refers to a kind of alloy with comprehensive properties such as high strength and certain anti-oxidation corrosion ability at 650~1000℃.

Stainless Steel Welded Tubes for Heat ex-changer

In addition to providing large-size welded pipes for chemical industry, we can also produce small-size tubes for heat ex-changers and boiler , which make up for the blank of ultra-thin heat ex-changer tubes.

Stainless Steel Welded Pipe for Chemical Industry

This is the dominant product of our company which is mainly applied as container or bearing pipe in oil refining, fine chemical industry, cold air [LNG, air separation unit, etc.], paper-making and shipbuilding areas.